Our Laboratory provides comprehensive measurement services for external customers. Thanks to our many years of experience and qualified staff, we guarantee high quality of services, short lead times and one of the lowest prices in our region.

The laboratory is equipped with apparatus for accurate measurements of:

– geometry: length, angle, flatness

– surface roughness

– hardness of ferrous alloy products ? using stationary and portable hardness testers by ?EMCO TEST? and ?KRAUTKRAMER-BRANSON?

The laboratory checks and calibrates measuring instruments for measuring length and angle, and classifies gauge blocks.

At the client?s request, we issue a certificate of the conducted tests. Measuring instruments are supervised in accordance with the requirements of ISO 9001 using specialised Q-MS/GM2000 software.

Measuring instruments:

Length gauge

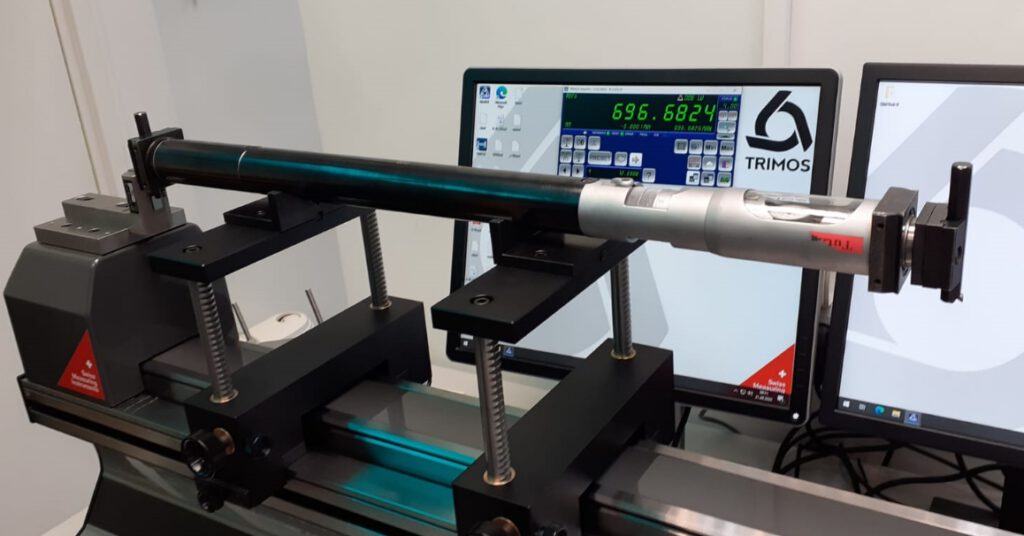

Horizon series precise length gauge for calibration and checking measuring instruments in the HPD 1500B version with a range of 0-1500 mm, manufactured by TRIMOS SA, Switzerland

Technical specifications:

External measuring range: 0 to 1550 mm

Internal measuring range: 1 mm to 1500 mm Accuracy: < MPE 0.7 ?m + (L (mm) / 1000)?m *

Repeatability: < 0.2 ?m

Resolution (switchable): 0.01 / 0.001 / 0.0001 mm

Measuring force (adjustable): 0 ? 12 N

Travel speed: 1.5 m/sec

Working temperature: +10 do +40C

Relative humidity: 20-80%

Calibrable

smooth ring gauges, reference rings ? 1 mm to ? 240 mm

Piston gauges (up to ? 100 mm)

Smooth roller and piston gauges up to 250 mm

Thread ring gauges (M5 to M180/56, pitch of 0.5 to 6 mm)

Thread piston gauges (up to M80, length 280mm)

Thread piston Gauges (up to M250)

H-type snap gauges (12 to 150mm/.473? to 6?)

H-type Outside micrometre gauge (50 to 1500mm/3? to 60?)

Setting/calibration of 2-point dial gauges

Lever gauges (diatests)

Gauges (dial gauges, etc. range up to 50mm)

Checking internal micrometers, micrometer setting standards

Brinell BH3000 hardness tester

Available measuring scales:

Brinell HBW10/3000, HBW10/1500, HBW10/1000, HBW10/500, HBW10/250, HBW10/100, HBW5/750, HBW5/250,

HBW2.5/187.5,

HBW2.5/62.5

Load range: 62.5, 187.5, 250, 500, 750, 1000, 1500, 3000kgf

Adjustable load application time in the range of: 2 to 99 s

Maximum vertical working space: 280 mm

Compliance with standards: ISO 6506, ASTM E10

Zeiss Contura coordinate measuring machine

Head type: VAST XT Measuring range: X = 700 mm, Y = 1000 mm, Z = 600 mm

Maximum permissible length measurement error as per ISO 10360-2: E0 = (1.5 + L/350)?m, PFTU = 1.5?m

Temperature range of guaranteed accuracy: 18-22°C

Scanning error as per ISO 10360-4: MPE_THP = 2.0 ?m in 40 s